Training Center

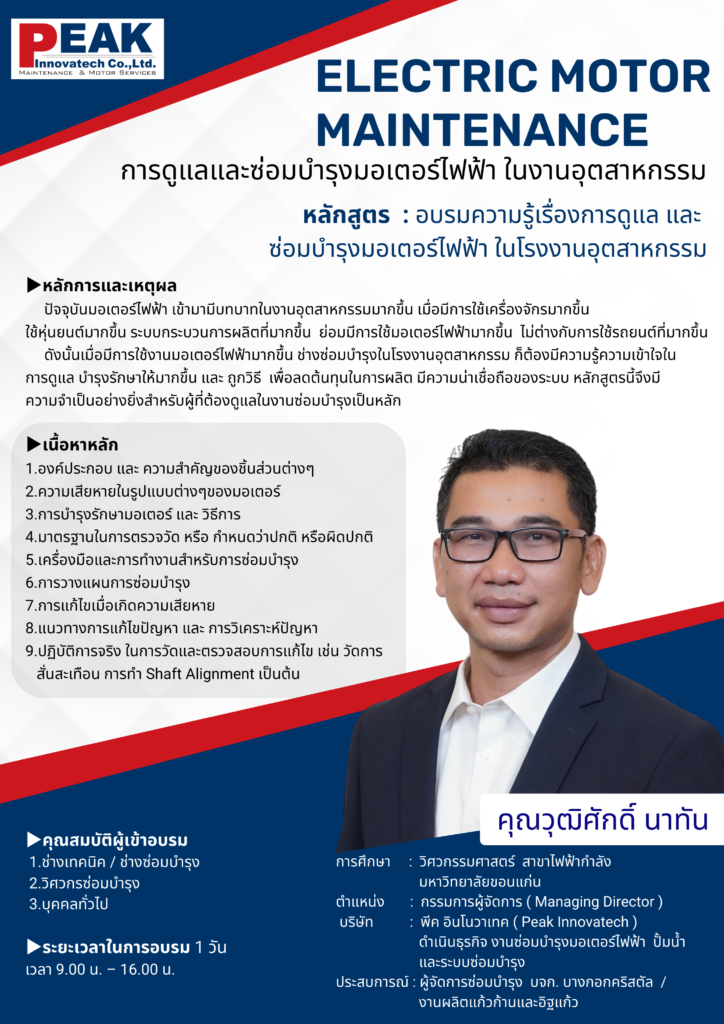

Electric Motor Maintenance

Principles and Rationale

Electric motors play an increasingly vital role in modern industry. As the use of machinery, robots, and production processes expands, the demand for electric motors grows proportionally. This trend mirrors the increasing use of automobiles. Consequently, as the utilization of electric motors rises, industrial maintenance technicians must possess a deeper understanding of proper maintenance procedures. This knowledge is crucial for reducing production costs and ensuring system reliability. Therefore, this course is essential for those primarily responsible for maintenance tasks.

Core Content

- Components and their significance within electric motors

- Various types of motor damage

- Motor maintenance procedures and techniques

- Standards for determining normal and abnormal conditions

- Tools and practices for maintenance tasks

- Maintenance planning strategies

- Troubleshooting and repair procedures for motor damage

- Problem-solving approaches and analysis techniques

- Practical exercises for measurement, inspection, and repair, including vibration measurement and shaft alignment.

Industrial Pump Repair & Maintenance

Principles and Rationale

In today’s world, water pumps are essential in various industrial settings, including factories, high-rise buildings, resorts, and other organizations. They play a crucial role in delivering water for various processes, making them indispensable equipment. However, many users and maintenance personnel lack the knowledge and skills required for proper pump maintenance and repair. This often leads to high maintenance costs and production disruptions due to water supply issues.

Therefore, the Industrial Pump Repair & Maintenance course is essential for maintenance technicians and business owners alike. It provides valuable knowledge and skills to ensure the efficient operation and longevity of industrial pumps.

Core Content

- Types of industrial pumps

- Components of industrial pumps

- Various forms of pump damage

- Methods for inspecting pump operation

- Maintenance planning strategies

- Troubleshooting and problem analysis techniques